Automation & Machine Customization

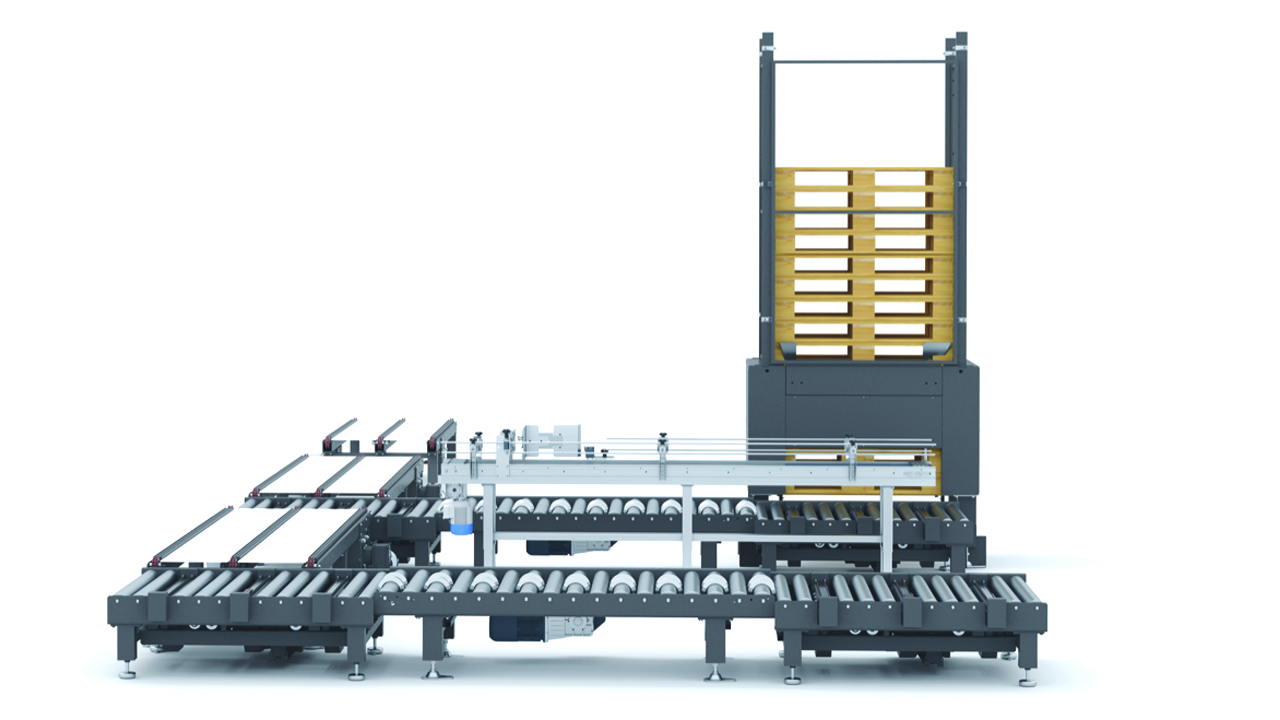

are mechanical systems designed to automatically return empty pallets from the end of a production or packaging line back to the loading or starting point. These conveyors operate along the same path as the main line (inline), ensuring efficient pallet circulation without manual handling. They are commonly used in automated material handling systems to improve workflow, reduce labor, and enhance safety.

Inline Pallet Return Conveyors

In electronics manufacturing, Inline Pallet Return Conveyors are used to efficiently manage the movement of pallets carrying delicate components or partially assembled devices. After products are assembled or inspected, the empty pallets are automatically returned to the beginning of the line for reuse. This system supports lean manufacturing, reduces manual handling of sensitive electronics, and helps maintain a clean, organized, and ESD-safe (electrostatic discharge) environment—which is critical in electronics production.

- Increased Efficiency: No delay in pallet availability for the next PCB.

- Labor Savings: Eliminates the need for manual pallet handling.

- Reduced Risk: Less human contact with fragile components, minimizing the chance of electrostatic damage or mishandling.

- Clean & Safe Workspace: Supports a well-organized, ESD-compliant production line.

Benefits of Inline Pallet Return Conveyor: