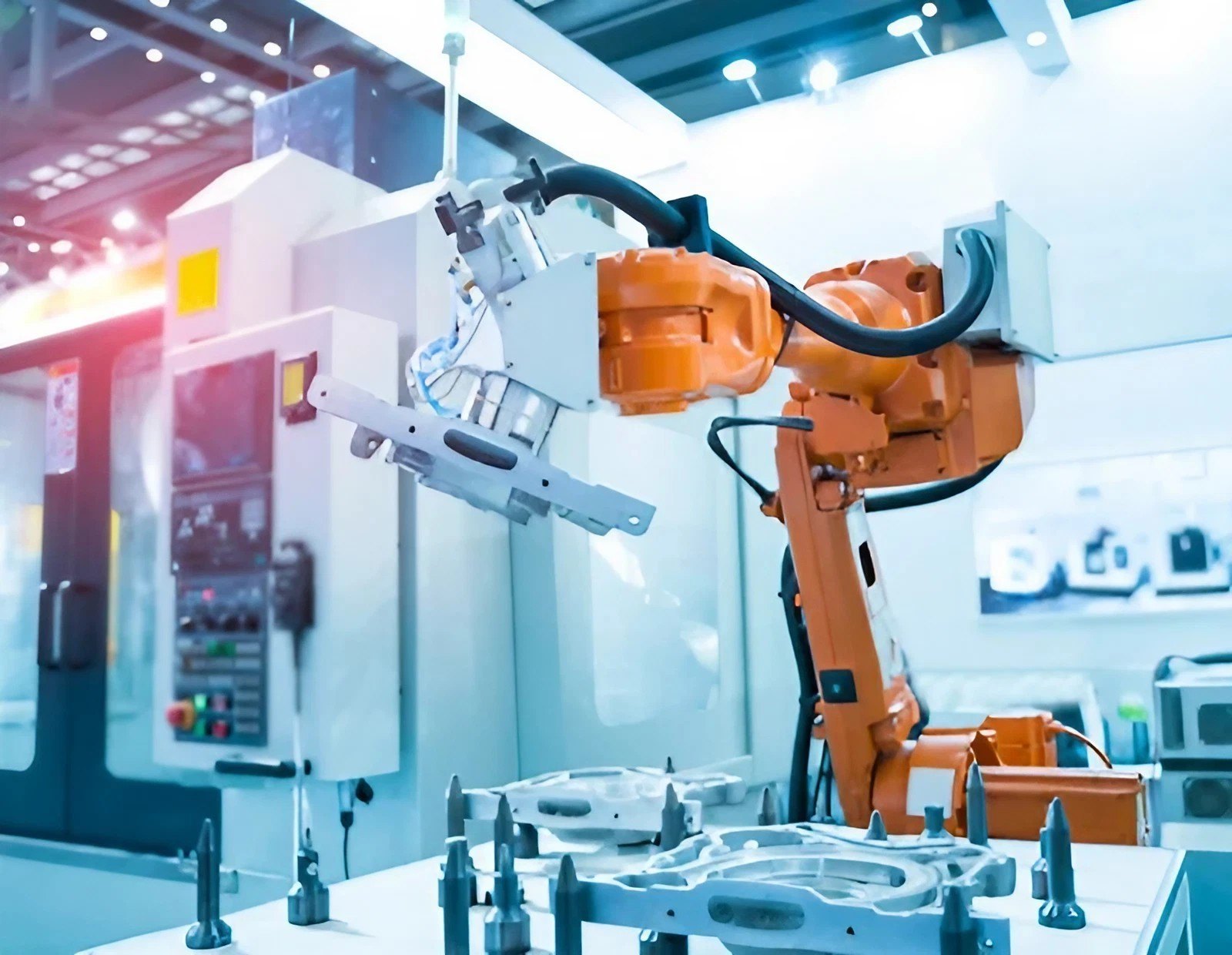

Automation & Machine Customization

Automated systems that use machine vision—typically a combination of cameras, lighting, image processing software, and algorithms—to inspect, measure, and evaluate products or components during manufacturing or assembly. These systems "see" and analyze visual data to detect defects, verify quality, and guide robotic actions based on visual input.

Vision-Guided Inspection Systems

In industrial settings, Vision-Guided Inspection Systems are used to automatically inspect manufactured goods for defects such as cracks, misalignments, missing parts, or incorrect labeling. The system uses digital cameras and intelligent software to replace or enhance human inspection, improving accuracy, repeatability, and efficiency on production lines.

- Cameras and Optics: Capture high-resolution images of objects.

- Lighting Systems: Ensure consistent and optimal illumination for image clarity.

- Image Processing Software: Analyzes captured images to detect flaws, misalignments, or deviations from specifications.

- Guidance Capability: Directs robotic arms or actuators to perform precise actions based on visual data (e.g., positioning, picking, or rejecting items).